In our day to day activities we use these terms to refer to the grade of the film. However, these terms actually refer to the manufacturing process of the film. Cast films have generally been considered the industry’s premium or long-term films while calendered films have been associated with intermediate or short-term uses. These days the difference between the films is not as great. Improvements in the calendaring process have given us a high-performance calendered film that can satisfy the needs of many sign makers.

It is safe to say that most people may not know the actual ingredients or manufacturing processes for these films. They do, however, know that a short-term film should not be used for a full vehicle wrap and that a cast or high-performance film is overkill for a point-of-purchase (POP) display that will only be used for six months to one year.

This article will explain the differences between cast and calendered films as well as give examples of where each type of film is best used.

What Makes Vinyl Vinyl

Let’s begin with a few of the basics on vinyl films. Most vinyl films are made from the same basic raw materials. We begin with polyvinylchloride (PVC) polymer, which is simply basic plastic, and is, by nature, relatively rigid. Other ingredients are then added to the PVC. These ingredients include: plasticizer to make the film flexible, pigment to make the desired color, and additives to help achieve specific properties such as UV absorbers to improve resistance to UV radiation, heat stabilizers, fillers and processing aids. These raw materials can be chosen from a wide range of quality levels. Of course, for a film with limited durability, often the least expensive raw materials are chosen.

Apart from the type of raw materials that are used at manufacturing, the manufacturing process and the type of plasticizer used create the main differences of vinyl films. Vinyl films can either be made by calendering or by casting. Each of these processes renders different qualities of films. Casting generally results in higher quality films. The grade of plasticizer that is used to make the film flexible also greatly affects the properties of the film. Generally for pressure-sensitive adhesive films a choice is made between polymeric and monomeric plasticizers. We won’t go into detail on the plasticizers in this article, but for simplicity’s sake consider polymeric to be the higher grade and monomeric to be the economy grade plasticizer. The combination of these factors greatly determines the durability of vinyl films.

Cast Films

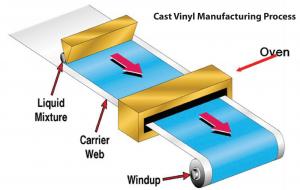

The term “cast” refers to the manufacturing process of this type of vinyl. Making a cast vinyl film is a lot like baking a cake. The vinyl begins with a “recipe” calling for a list of ingredients known as the formulation. These materials are added to a “bowl” or mixing churn in a predetermined order while mixing at specific speed and for a set amount of time to ensure a complete and consistent mixture. This liquid mixture, known as organosol, is then precisely metered or cast onto a moving web known as the casting sheet and is then processed through a series of ovens which allows for the evaporation of solvents. When the solvents are evaporated, a solid “film” is left behind. The film is then wound up in large-diameter rolls for subsequent adhesive coating. The casting sheet determines the texture of the film.

Because the vinyl is cast on the casting sheet in a relaxed state, this material offers very good dimensional stability. This process also allows the film to be very thin (most cast films are 2 mil), which helps with the conformability of the product. Material manufacturers recommend the use of cast films on substrates such as fleets, vehicles, recreational vehicles or boats where the customer wants a “paint-like” finish that will last a long time, usually five to 12 years depending on how the film is processed.

Advantages of cast films:

Shrinkage is the lowest of all vinyl films because the “casting sheet,” not the film itself, is pulled through the machine. Since the film has not had any stress applied during the manufacturing process it does not try to resume or shrink back to its original form.

Durability of cast films is generally higher than that of other vinyl films due to the manufacturing method and the raw materials used.

Cast films can be made very thin which produces a conformable product that allows application over substrates with rivets, corrugations, and complex curves. Also, once applied, this low caliper makes the graphic less vulnerable to abrasive forces.

Cast films also maintain their color and other properties better than other vinyl films. This results in better performance of pigments and UV absorbers.

The manufacturing process of cast films makes it easy to run small productions of special colors to match. It is relatively easy to change color during production making color matching in small batches possible.

Calendered Films

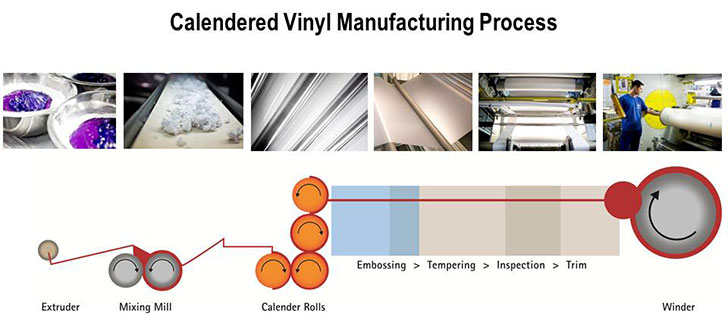

Like cast, calendered film also gets its name from the manufacturing process. The production of calendered film is similar to mixing and rolling out a pie dough. It is formulated with similar raw materials as cast. These ‘ingredients’ are mixed and later ‘kneaded’ in the extruder. Instead of grandma’s rolling pin, gigantic heated, steel rollers form the vinyl into a thin sheet. This process is called ‘calendering’.

The first step is ‘paste mixing’ and ‘extrusion’: here all raw materials (e.g. PVC powder, liquid softener, colors) are mixed together based on the formulation. Improved formulations and the use of new pigments lead to increased color options for calendered film. In the extrusion process the prepared fine powder mix (‘dry blend’) will fuse together into a homogenous mass, called the melt. The next step – the mill – consists of two counter rotating rolls, which can be heated up to 350 °F. The melt is continuously pulled into the gap and flattens out due to the pressure and temperature that is applied by the mill rolls. When the strip reaches the calender rolls, it passes between multiple gaps which increase the temperature and uniformity. After each gap the film becomes thinner and wider according to the specifications. The film is still heated when it reaches the embossing station where different pattern and gloss levels are applied to the film. Each surface structure requires a different embossing roll – e.g. to produce a high gloss film a different embossing roll is required but also a special setting of the whole calender line. Now that the film has received its final dimensions and surface it needs to be cooled down and transported to the last process stage of winding.

From the extruder to the winder a calender machine can be 90 feet long. Due to improvements made in the manufacturing process, calendered film can be produced as thin as 2.0 mil.

The quality of calendered films can range from economy, which use a monomeric plasticizer, to a high-grade which would use a polymeric plasticizer. The durability of calendered films can range from one year up to seven years.

Advantages of calendered films:

Today’s calendered films are thinner, glossier, have better conformability and less shrinkage than calendered films made years ago.

Greater production yields less cost

Stiffer/thicker film equals easier handling

Excellent performance on flat, simple and moderate curves

Today’s calendered films have a greater variety of colors as well as a wide range of gloss levels.

Shrinkage of polymeric or high grade calendered films can be as low as 2-3%

Formulation of film increases resistance to abrasion

The chart below lists several attributes of cast and calendered films and how they compare to one another.

As with anything else, the finished product is only as good as what you put into it. This begins with choosing the right vinyl for the job. If you are doing a full vehicle wrap where you want the graphic to conform so that it looks and performs similar to paint you should choose a material with these characteristics, which would be cast film. Calendered films are ideal for applications that do not require the film to stretch or conform around complex contours. Examples of calendered film uses would be floor graphics, wall murals, window graphics, partial wraps and point-of-purchase displays.