San Leandro, CA – Skate Shop News: What is a Skateboard Made of?

Posted in: Uncategorized

There are a lot of different parts on a skateboard, but one of the most obviously important is the skateboard deck. The skate deck is the flat board that you stand on when skateboarding. A shortboard, as opposed to a longboard or cruiser, is ideal for street skateboarding and vert skateboarding. It also remains the very best option for doing tricks, whether you are a beginner or a pro.

There are a lot of different parts on a skateboard, but one of the most obviously important is the skateboard deck. The skate deck is the flat board that you stand on when skateboarding. A shortboard, as opposed to a longboard or cruiser, is ideal for street skateboarding and vert skateboarding. It also remains the very best option for doing tricks, whether you are a beginner or a pro.

There are a few things to consider once you decide to build a complete skateboard, and picking the right size of deck is the first of many choices you’ll make. Choosing board shape is also super important. The length, width, materials, and concave of your skateboard deck determine what you will be able to do on your skateboard.

Depending on how hard you skate, you’ll want to replace your skateboard deck anywhere from after a few weeks to a year. Once the sides, nose, or tail of your skateboard deck  show signs of splitting, it’s time to start with a fresh board. Riding in wet or cold areas can also warp the shape of your board and make your skateboard wheels uneven, so be sure to replace your board if you feel or see any signs.

show signs of splitting, it’s time to start with a fresh board. Riding in wet or cold areas can also warp the shape of your board and make your skateboard wheels uneven, so be sure to replace your board if you feel or see any signs.

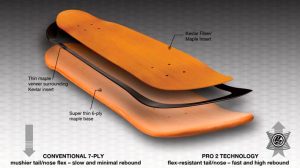

Maple wood is an ideal wood type for skateboards; it is flexible, yet durable, allowing it to be easily shaped without sacrificing strength. It’s still the most common material used for skateboard decks. Even within maple decks, the amount of ply can vary. Ply is the measure of how many thin sheets, or veneers, of wood make up the deck. These wood veneers together actually make for a stronger board than a single, solid plank. The most common construction is 7-ply, though decks may increase or decrease veneer to either increase strength or decrease weight.

Constructing a skateboard deck begins with placing the veneers on top of one another. Beyond the amount of ply, the direction the wood grain is facing can make a big difference in the board’s performance. Alternating between veneers that run lengthwise and veneers that run widthwise, or cross-beaming, can increase the board’s durability. Once the veneers are glued into place, they are formed under a hydraulic press, which compresses the wood layers into a single, sturdy strip. This is also the stage of the process where the unique nose, tail, and concave of the board are formed–the press bends the wood layers into shape. The board is left in the press while the glue sets, and this too can play a part in the board’s ultimate performance. The longer the glue sets, the more naturally the board is held together.

Constructing a skateboard deck begins with placing the veneers on top of one another. Beyond the amount of ply, the direction the wood grain is facing can make a big difference in the board’s performance. Alternating between veneers that run lengthwise and veneers that run widthwise, or cross-beaming, can increase the board’s durability. Once the veneers are glued into place, they are formed under a hydraulic press, which compresses the wood layers into a single, sturdy strip. This is also the stage of the process where the unique nose, tail, and concave of the board are formed–the press bends the wood layers into shape. The board is left in the press while the glue sets, and this too can play a part in the board’s ultimate performance. The longer the glue sets, the more naturally the board is held together.

Next, holes will be drilled into the deck to allow trucks to be attached. From there, a band saw is used to cut the deck’s shape from the large piece of formed wood, which is then  rounded and sanded smooth. The deck is also varnished and sealed to protect the wood against warping and getting damaged. Lastly, manufacturers will add graphics to the deck. Many skateboards are screen-printed, though some companies offer custom hand painting as well. The skateboard deck will dry and set in the factory until it is ready to be sold.

rounded and sanded smooth. The deck is also varnished and sealed to protect the wood against warping and getting damaged. Lastly, manufacturers will add graphics to the deck. Many skateboards are screen-printed, though some companies offer custom hand painting as well. The skateboard deck will dry and set in the factory until it is ready to be sold.

The art of skateboard manufacturing has been refined over the past few decades, and manufacturers are constantly experimenting with new technology, materials, and graphics trends.

The art of skateboard manufacturing has been refined over the past few decades, and manufacturers are constantly experimenting with new technology, materials, and graphics trends.

Orbit Skate offers a huge selection of skateboard decks in a variety of shapes, sizes, weights, colors, and patterns. Check out our huge deck wall, or ask one of our knowledgable staff members to help you find the skateboard deck that suits your style!

Return to: San Leandro, CA – Skate Shop News: What is a Skateboard Made of?

Social Web