Calendered or Cast Vinyl?

Posted in: Industry News

When choosing between two products that look virtually the same on the surface, there’s usually no doubt that you should pick the cheaper one. After all, why spend more money for a designer brand when the generic form looks and feels almost identical?

When it comes to vinyl, however, the truth is that there is a difference in the quality of the material that you purchase. The difference between calendered and cast vinyl – the two types of vinyl used in signage – is created in the manufacturing process. Although the applications are quite straightforward, the actual process by which each type of vinyl is produced is very different.

In the following post, we’ll explain what vinyl is, break down the process by which calendered and cast vinyl are each made, and give you a better understanding of what each material means!

What is vinyl?

Vinyl is a rigid material with a PVC base. Other ingredients are then added to the PVC; plasticizer to create flexibility in the final film, additives to achieve certain properties (this can be anything from heat stabilizers to fillers to UV absorbers to help the final vinyl better resist UV radiation), and pigment to create a specific color.

The main property that sets cast and calendered vinyls apart is the manufacturing process…

Cast films

Cast vinyl is named because of the manufacturing process, in which the vinyl solution is “cast” onto a moving belt, or casting roller. The whole process begins by mixing the solution, which, generally speaking, is made of higher quality materials than calendered vinyl. The resulting mixture is then “cast” onto the roller, where it’s sent through a series of ovens, baking out solvents. And voila! You have cast vinyl. After the solvents are dissolved, there is a 2 mil sheet of vinyl left.

Advantages of cast films

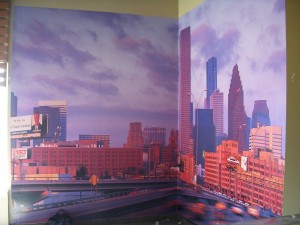

Because cast vinyl is made with virtually no stress from heat or pressure, it is in a much more natural state than calendered vinyl, making it better suited to long term exposure to extreme cold, or, more relevant in Houston, heat. Additionally, this process prevents the material from shrinking back to it’s original form because it’s never been altered from it in the first place!

At only 2 mil thickness, cast vinyl is extremely thin, allowing it to conform very easily to oddly shaped or textured surfaces, making it the perfect for a variety of applications…

What should cast vinyl be used for?

Cast vinyl has a lifespan of up to 12 years, depending on conditions, and is designed to last well in all sorts of conditions. On top of its great durability, cast vinyl’s conformability makes it the perfect material for vehicle wraps or graphics, or any situation where the customer wants a “paint-like” finish.

Calendered vinyl

There are two major types of calendered vinyl: monomeric and polymeric (or high grade calendered vinyl). Although polymeric calendered vinyl has a slightly longer lifespan and better durability, both vinyls are manufactured using the same process.

All of the ingredients are mixed together and heated, creating a “melt”, which is then pulled between two rollers (also known as the mill). During this step of the process, the vinyl is subjected to huge amounts of heat and pressure, leaving it with little dimensional stability. This means that calendered vinyl products are subject to shrinking in extreme heat or cold, which can lead to cracking, bubbling, or adhesive oozing from the sides – none of which scream “high quality”.

`

But does that mean that calendered vinyl is bad? Not at all! It just has different advantages and uses…

Advantages of calendered vinyl

To start, calendered vinyl is much easier to mass produce, making it a much less expensive product! Although this by itself isn’t a reason to buy calendered vinyl over cast vinyl, if you’re looking for short term applications out of extreme weather conditions, calendered vinyl is a great choice.

Additionally, calendered vinyl is manufactured with 3 mil thickness, making it slightly stiffer and sturdier than cast vinyl. Although this makes it less possible to shape to odd structures such as cars, calendered vinyl performs well on flat or moderately curved surfaces, and withstands abrasion well!

What should calendered vinyl be used for?

As a general rule, calendered vinyl should be used indoors, for anything from wall graphics to indoor window lettering.

Just remember: the finished product is only as good as what you put into it. If you’re looking for a product that is going to last more than a couple years, or is going to be exposed to outdoor conditions, opt for cast vinyl!

832-688-8709

Written by: Signs of Success – Houston, TX

Return to: Calendered or Cast Vinyl?

Social Web